CEMS maritime

NDIR - Gas analyzer for Scrubber

This system for Continuous Emission Monitoring (CEMS) is built for the maritime use. It has been specially developed for analyzing gas concentrations in DeSOX applications (Scrubbers). Where ship emissions are limited by regulation (ECAs), our system can be integrated for monitoring SO2 and CO2. The compact box includes a precise and efficient NDIR sensor, a gas dryer, a human machine inferface, pumps, analog outputs and Modbus communication. By operating the NDIR sensor in change flow mode, a stable zero point can be ensured over long time periods.

Measurement principle:

SO2 and CO2 are measured by a nondispersive infrared (NDIR) analyzer.

Since we are not using any moving parts in our NDIR module, we can ensure a long term operation with fewest maintenance needs.

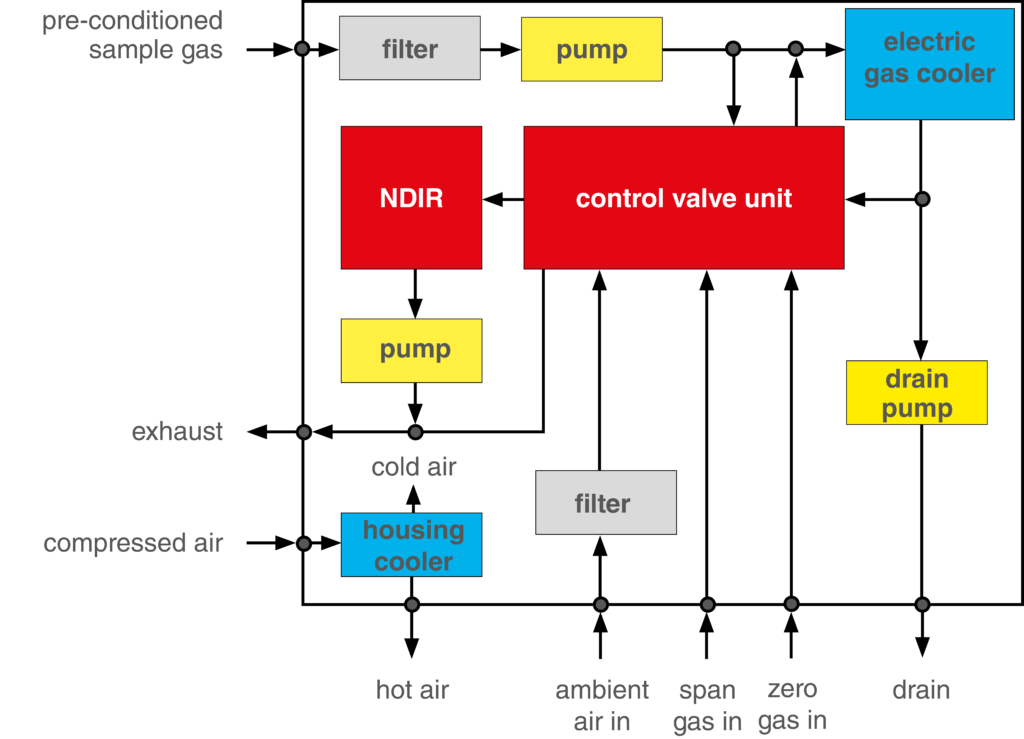

As sample gas enters the analyzer, it gets precisely cooled down to 4°C, which minimizes humidity influences. Additional pressure regulation as well as temperature regulation allow measurements with highest accuracy.

A Control Valve Unit enables a change-flow-mode technique to ensure a long-term stability.

Size: 687 x 860 x 360 mm

Flow chart

- Simultaneous measurement of Simultaneous measurement of CO2 and SO2

- Easy & flexible installation due to compact size

- Long-term stability due to operation in chage flow mode

- Robust against harsh environmental conditions

- Analyzer performance in accordance with the NOX 2008 / MEPC 177(58) technical regulations

- An integrated housing cooler ensures stable air conditioning inside the box.

- Change flow mode: The internal control valve unit manages a continuous zero point correction for a stable zero point.

- An integrated HMI manages the analog and digital communication as well as the 7″ touchscreen for operation.

- The valves, pumps, filters and gas cooler are arranged in intelligent modules that can be replaced quickly and easily.

- Optimized service and maintenance options provide uncomplicated support for the system integrator.

- The IP43 housing is mounted with damping elements so that it can withstand all types of vibrations.

| Measuring range1 | |

|---|---|

| SO2 | 0 – 250 ppm |

| CO2 | 0 – 20 % |

| 1 other measuring ranges upon request | |

| Specifications | |

|---|---|

| Accuracy | ≤ ± 2 % of reading or 0,3 % of full scale |

| Noise | ≤ ± 2 % of full scale |

| Zero drift | ≤ 2 % of full scale in 1 h |

| Span drift | ≤ 2 % of full scale in 1 h |

| Precision | ≤ ± 1 % of full scale |

| Response time | < 30 s |

| Ambient conditions | Temperature: -5 to 45 °C, Humidity: < 90%, |

| Sample gas | Filtered, heated sample gas line (no condensation) |

| Gas flow | 3 l/min(1), warning message for incorrect flow values |

| Power supply | 90 – 264 V AC/50 – 60 Hz, internal safety management, max. power consumption 380 W |

| Dimensions | 860 x 687 x 360 mm |

| Assembly | Wall installation under shelter or installation in control room |

| Analog output | Current output 4 – 20 mA for each measured gas |

| Digital output | Analyzer calibration status |

| Communication | Modbus TCP/IP |

| Weight | 40 kg |

| Connections | zero gas, combined span gas, sample gas, exhaust, drain, compressed air |

| Zero point correction | Automatically done by change-flow-mode |

| Interface | Integrated HMI with 7″ LCD (capacitive touch) |

| 1 can be adjusted if necessary | |

- Simultaneous measurement of Simultaneous measurement of CO2 and SO2

- Easy & flexible installation due to compact size

- Long-term stability due to operation in chage flow mode

- Robust against harsh environmental conditions

- Analyzer performance in accordance with the NOX 2008 / MEPC 177(58) technical regulations

- An integrated housing cooler ensures stable air conditioning inside the box.

- Change flow mode: The internal control valve unit manages a continuous zero point correction for a stable zero point.

- An integrated HMI manages the analog and digital communication as well as the 7″ touchscreen for operation.

- The valves, pumps, filters and gas cooler are arranged in intelligent modules that can be replaced quickly and easily.

- Optimized service and maintenance options provide uncomplicated support for the system integrator.

- The IP43 housing is mounted with damping elements so that it can withstand all types of vibrations.

Measuring Range

| Measuring range1 | |

|---|---|

| SO2 | 0 – 250 ppm |

| CO2 | 0 – 20 % |

| 1 other measuring ranges upon request | |

Specifications

| Specifications | |

|---|---|

| Accuracy | ≤ ± 2 % of reading or 0,3 % of full scale |

| Noise | ≤ ± 2 % of full scale |

| Zero drift | ≤ 2 % of full scale in 1 h |

| Span drift | ≤ 2 % of full scale in 1 h |

| Precision | ≤ ± 1 % of full scale |

| Response time | < 30 s |

| Ambient conditions | Temperature: -5 to 45 °C, Humidity: < 90%, |

| Sample gas | Filtered, heated sample gas line (no condensation) |

| Gas flow | 3 l/min(1), warning message for incorrect flow values |

| Power supply | 90 – 264 V AC/50 – 60 Hz, internal safety management, max. power consumption 380 W |

| Dimensions | 860 x 687 x 360 mm |

| Assembly | Wall installation under shelter or installation in control room |

| Analog output | Current output 4 – 20 mA for each measured gas |

| Digital output | Analyzer calibration status |

| Communication | Modbus TCP/IP |

| Weight | 40 kg |

| Connections | zero gas, combined span gas, sample gas, exhaust, drain, compressed air |

| Zero point correction | Automatically done by change-flow-mode |

| Interface | Integrated HMI with 7″ LCD (capacitive touch) |

| 1 can be adjusted if necessary | |

Need help?

We look forward to help you choose the perfect gas analysis products for your needs. Talk to us about different technologies and our gas analyzers or OEM sensors.