Welcome back for Part 3 of our OEM assembly blog special. Since over the past few years, the requirements for gas analyzers have become increasingly demanding, we have come up with a solution to easily combine the components you need in a flexible gas analyzer setup: the TRACE-GAS OEM assembly.

In Part two we showed you assemblies with NOx converter, Ozone destroyer and regulated pump. In this part we will cover examples for the Temperature Control Module, Sensor Extension Module, Pressure Control Module and HMI

With TRACE-GAS OEM Assemblies, you can easily configure your own analyzing solution. Our OEM assemblies will not only speed up your development process, but are also very small and work plug & play!

Over the recent years, we have developed solutions for many customers with different needs in sampling, communication and ambient conditions. Consequently, our product range of additional sensor components has increased over time. Now, we want to share these OEM assemblies with you.

Our OEM assemblies allow you to…

- Speed up your design and implementation process

- Save time analyzing and testing various products

- Use the modules plug & play

- Minimize the support effort with various suppliers

All our modules communicate by CAN and require a 24V power supply, but our preconfiguration allows the user to use it plug and play. Our OEM assemblies can be combined with our OEM sensor or can be used standalone in a custom configuration.

Temperature Control Module

Temperature is a key parameter in every sensor system, especially in gas sensing. Temperature stability can improve measuring results similar to pressure stability. However, stability is not the only reason why temperatures need to be controlled. Applying too high temperatures inside a system can lead to overheating of components, whereas lower temperatures increase the risk of forming condensation at critical positions. Every gas analyzer system requires some sort of temperature control.

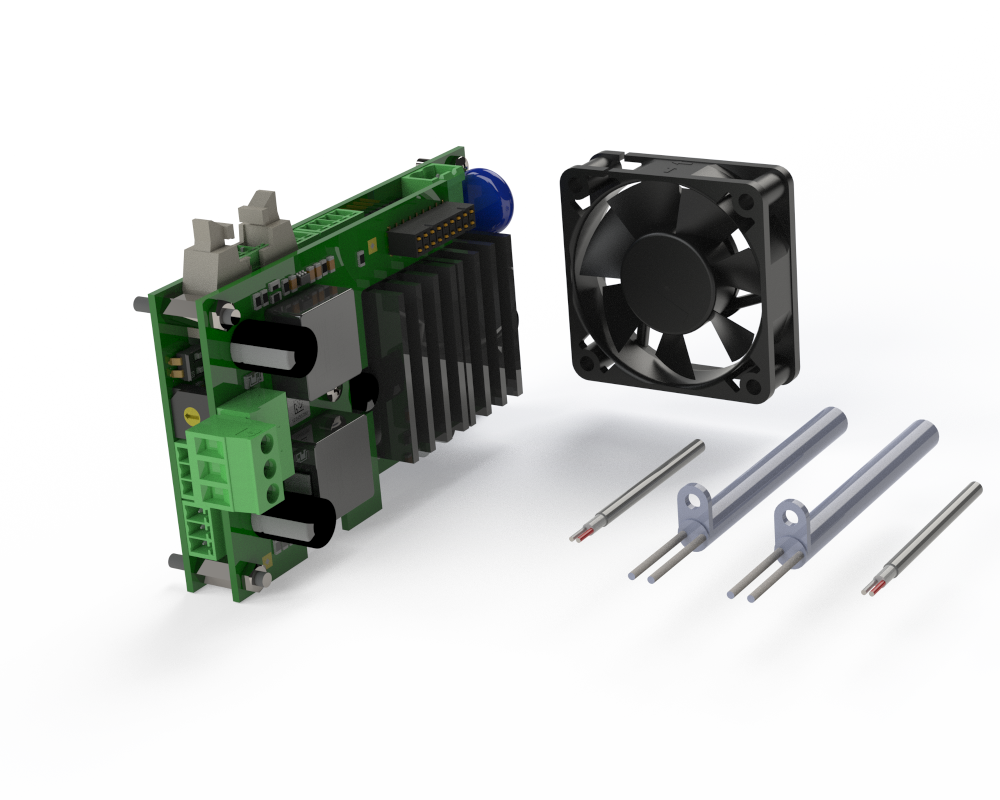

Each Temperature Control Module consists of two high precision temperature circuits, which can be operated separately. Both consist of a temperature sensor input (PT100 or thermoelement) as well as a temperature control output used with 24V pulse width modulated signals. These can be used with Peltier elements (also for cooling), heating cartridges or any other 24V heating/cooling components. In addition, 5V or 24V fans can be operated with the module.

The Temperature Control Module has been developed as flexible solution to all temperature control tasks. It is used in many of our products, like our LASmini sensors. These sensors are used in hot-wet combustion analysis and therefore require a heated measuring chamber at 190 °C in order to avoid condensation. Two PT100 temperature sensors are placed inside the insulation at different positions of the chamber and measuring the actual temperature. In order to maintain the temperature setpoints, two heating cartridges are used to keep the temperature at constant 190 °C for both positions indivually. If the sensor is mounted in a 19-inch housing, the temperature module can further be used as a housing cooler operating a fan.

The temperature module can handle both PT100 and thermoelements and can operate a variety of 24V heating and cooling elements. Temperatures can be controlled with high precision and two fans can be connected.

LASmini

LASmini with built-in temperature control module

Temperature control module

Overview:

- 2x temperature sensor input (PT100 and thermoelement possible)

- 2x 24V temperature controller output

- 24V and 5V fan output

- For heating and cooling

- Used with heating cartridges, Peltier elements, fans etc.

Note: Our gas cooler module is including a temperature control module

Sensor Extension module

Many applications require a variety of gases to be detected simultaneously. Some of them are preferred to be measured by techniques other than optical gas sensing. One example is oxygen, which is often measured by electrochemical (EC), zirconia (ZrO2) or paramagnetic sensors (PMA). Since each of them are different, the best solution must be chosen by evaluating the required process specifications as well as the regulations that might be given by industry or legislation. Another example are permanent and inert gases, which can be measured by thermal conductivity detectors (TCD) in a cost-efficient way.

Our Sensor Extension Module provides the opportunity to use these technologies (EC, ZrO2, PMA, TCD) in only one product with each of them to be heated during operation. Furthermore, an NDIR sensor, two temperature sensors as well as three pressure sensors can be applied.

It’s an ideal solution for applications requiring further technologies by regulations, especially for oxygen measurements.

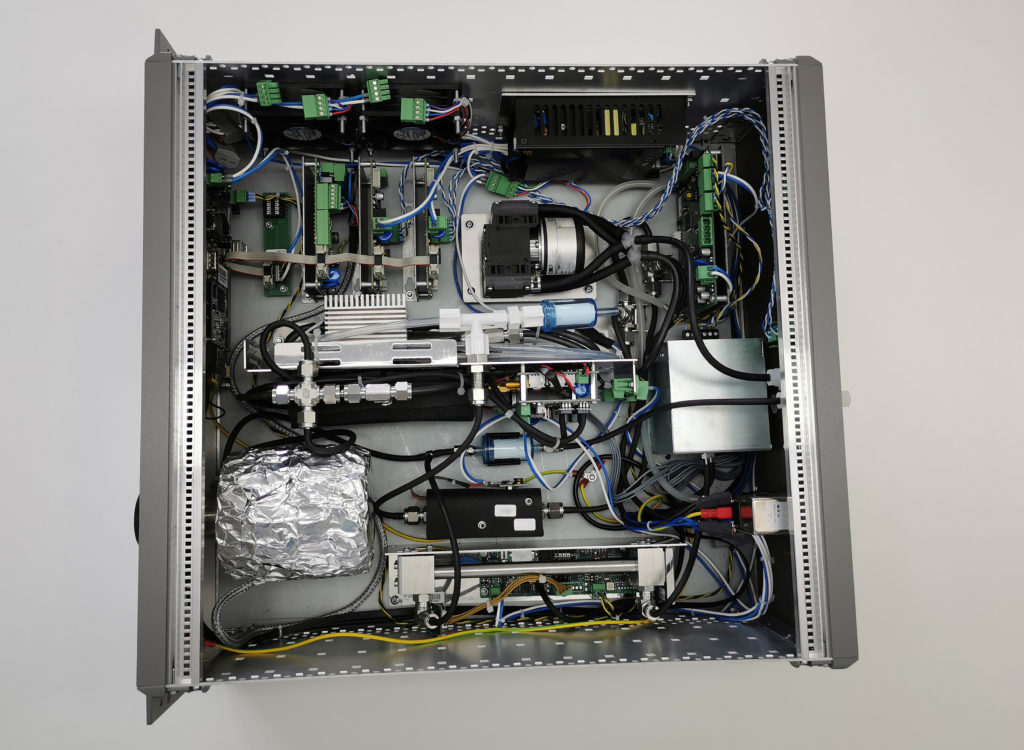

Example for combing different sensor technologies and assemblies: CLDmini (center), paramagnetic oxygen sensor (right), NDIR sensor (bottom), NOx Konverter (left)

Overview:

- 1x Non-Dispersive Infrared NDIR sensor

- 1x Electrochemical (EC) sensor

- 1x Zirconia (ZrO2) sensor + temperature output

- 1x Paramagnetic (PMA) sensor + temperature output

- 1x Temperature Conductivity Detector (TCD) + temperature output

- 3x pressure sensor

- 2x Temperature sensor (digital + PTC)

HMI

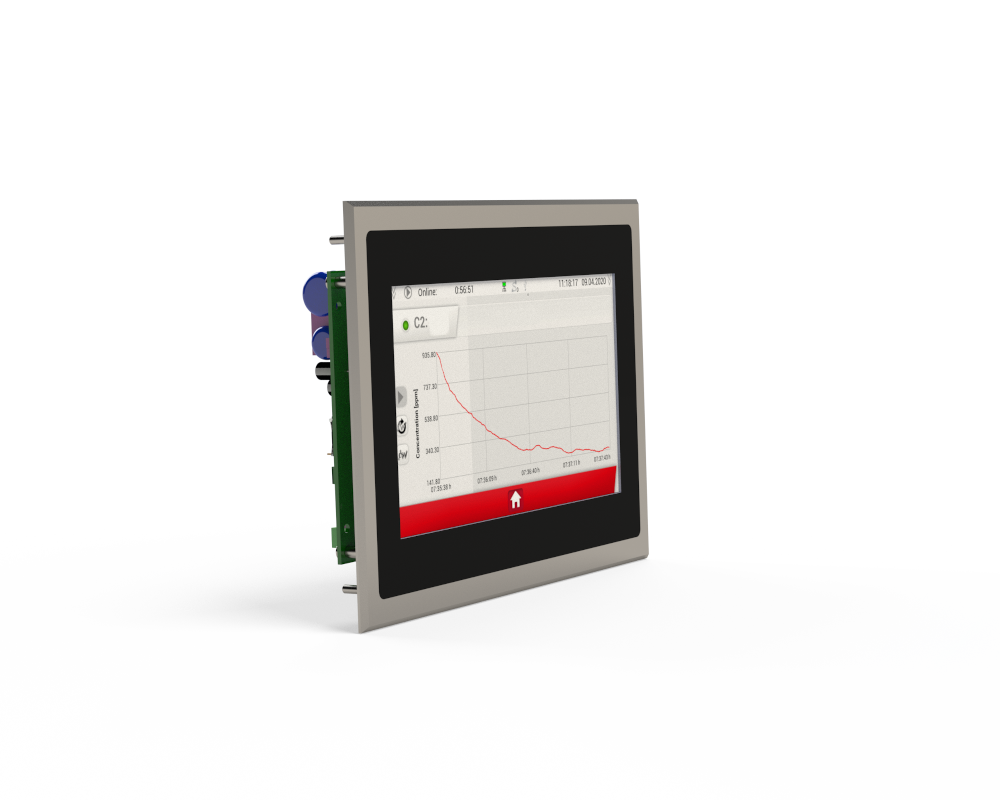

A human-machine-interface (HMI) simplifies the operation of sensors, analyzers as well as complete systems. Via display and touch screen the user can monitor, control and maintain its device.

The HMI consists of a display unit and the control board. The display unit allows the user to control the device by a 7-inch capacitive touch screen, whereas the control board is the actual brain. It is communicating to various sensors and further OEM assemblies connected on the internal CAN BUS system inside our ready to use sensors and complete solutions. To the end customer, it can also operate as a gateway, which allows to use some modern protocols like Modbus TCP/IP. Also updates can be made by using an USB interface.

The HMI Software is continuously extended and many functions have been implemented so far. E.g. a datalogging function allows our customers to simply plot their measurement results on the display and even export the data to a USB device. Of course, calibration procedures can be executed with the HMI within some seconds. The user can also check the conditions of each component connected.

The HMI can be used in combination with any of our sensors and OEM assemblies. The picture below shows an example of the HMI being mounted in our ready-to-use LAS H2O2 analyzer. The analyzer consists of mainly a LAS sensor, an analog output module and a pump module. All these components are connected to the internal CAN BUS and the HMI is displaying the measured gas concentrations and is supervising the status of each component.

The HMI is very flexible due to its many functions, a variety of communication interfaces as well as the compatibility to all TRACE-GAS products.

Overview:

- Consists of display unit and control board

- 7-inch capacitive display

- Compatible with all TRACE-GAS Products

- Many communication interfaces

- Implemented Functions: Data logging, Data Plot, Data Export, USB Update, Calibration modes, Information menu, Sensor Settings and many more…

HMI Human Maschine Interface

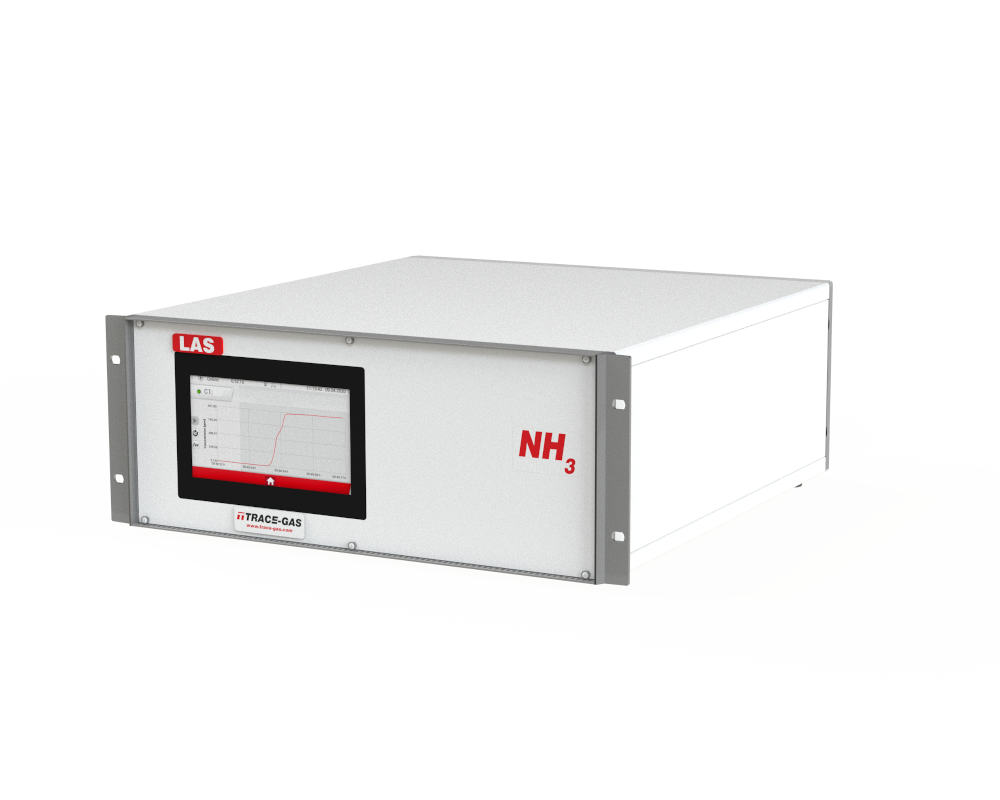

LAS analyzer NH3 with touch HMI

Chemiluminescence analyzer NOx with touch HMI

Pressure Control Module

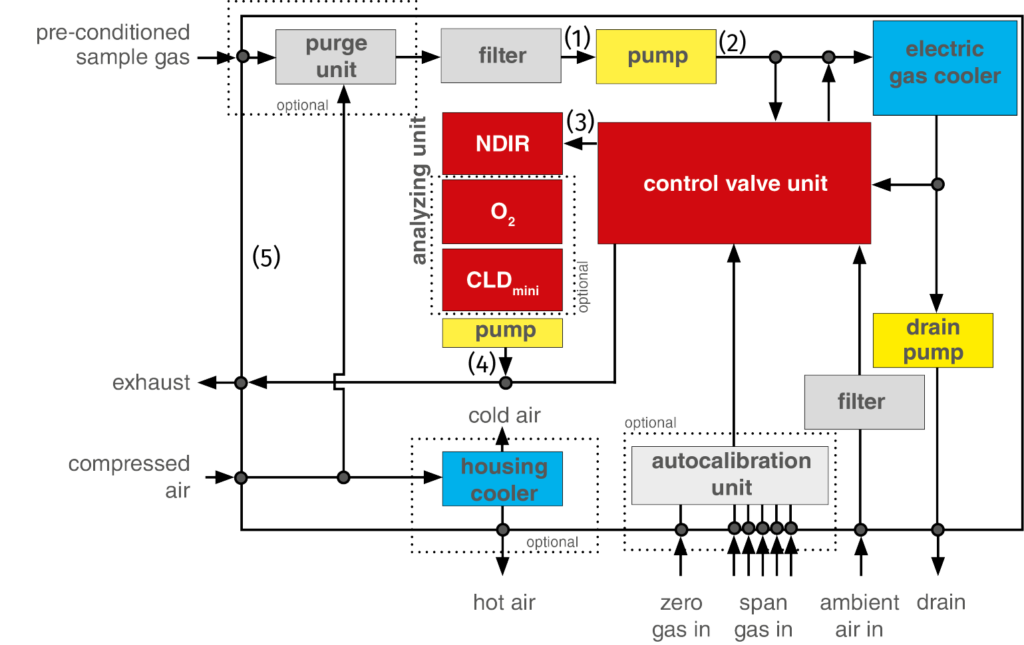

Stability is a key for stable measurements. If highest stability is required in each mode of operation, a constant pressure and flow will improve your measurement results by far. As an example, NDIR sensors will perform best if both parameters are regulated at constant values. In other applications, the sensor might require vacuum for reasons like avoiding condensation, minimizing adsorption effect, lowering cross sensitivities etc.

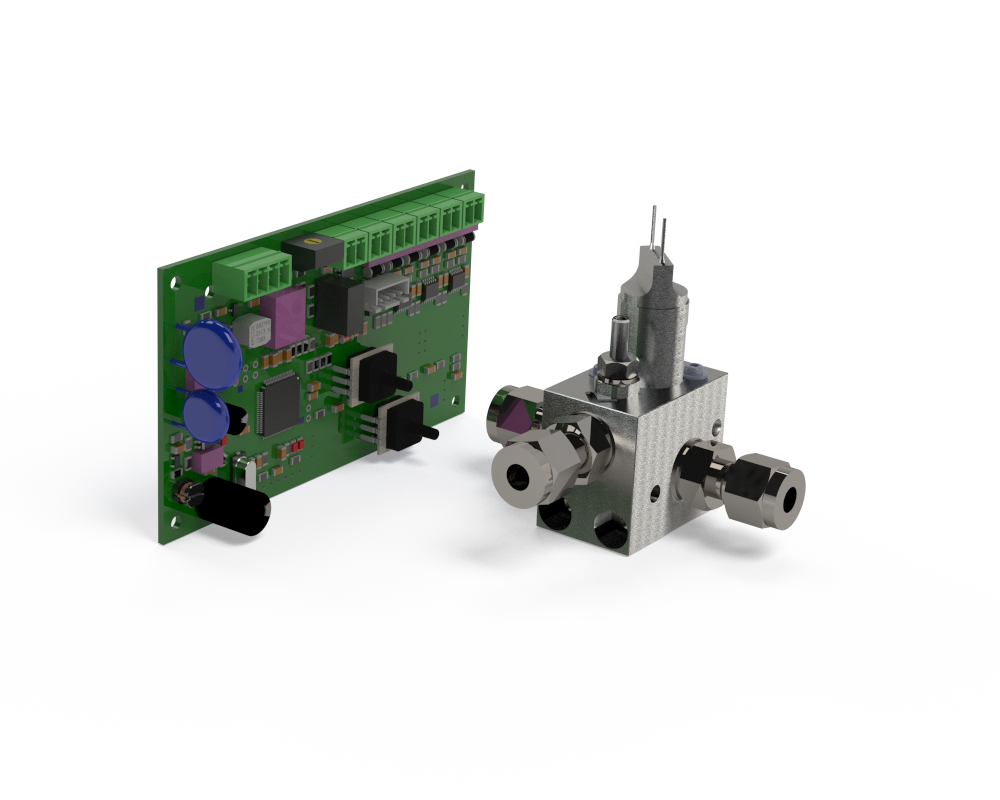

The pressure control unit consists of a proportional valve and a pressure control board. A pressure sensor, mounted on the pressure control unit, is connected to the position of interest in the flow setup. By using pulse width modulation (PWM) signals, the proportional valve is maintaining the pressure setpoint given by the user.

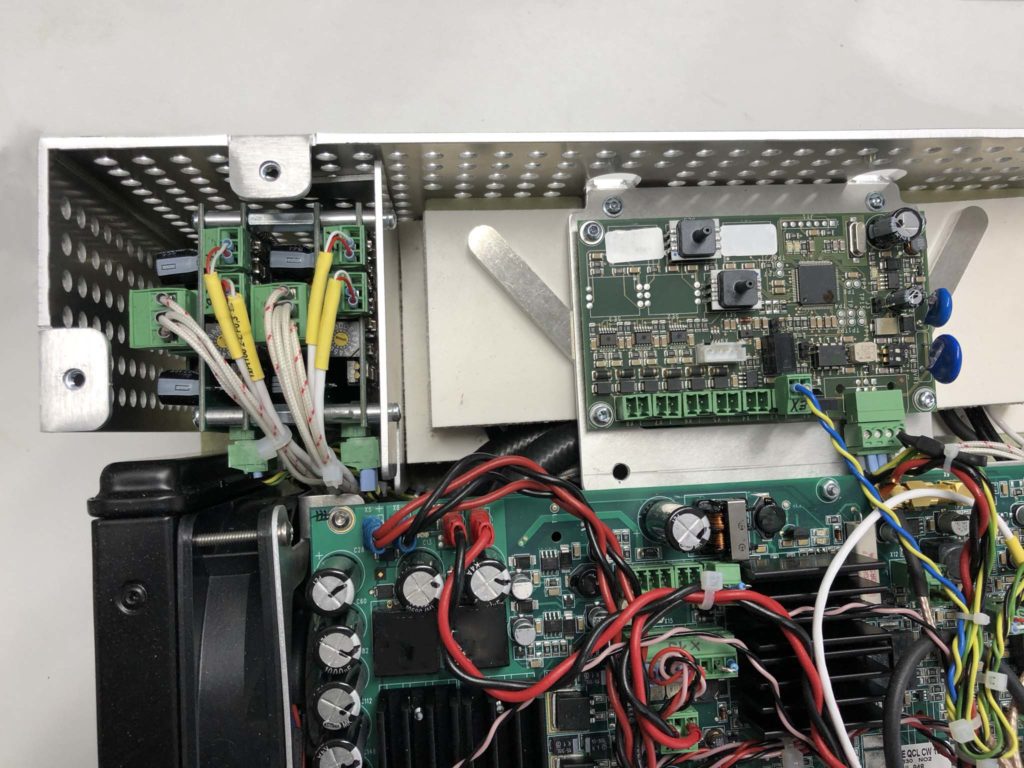

In our CEMS in a box solution, the pressure control board is used for many functions. For monitoring the dust load of the filter element, two pressure sensors are measuring its pressure difference (1+2). In order to achieve highest signal stability, one output is used to maintain the NDIR sensor pressure by a proportional valve (3), whereas another is controlling the sample pump (4) in order to achieve a constant gas flow. A further output is used to control a housing cooler operated by instrument air (5).

The pressure control module is compact and offers highest flexibility. In addition to simple pressure control functions, the module can be extended with a variety of pressure inputs and further components like pumps.

Pressure control module

Overview:

- Consists of pressure control board & proportional valve

- Alternative use with regulated pump

- Extendable up to 6 pressure sensors and 6 PWM outputs

- ideal for pressure monitoring of complete systems

As the blog series has surely shown, there is a wide variety of possible component combinations. So if you have different assembly needs, don’t hesitate to reach out to us with any questions.