Over the past few years, the requirements for gas analyzers have become increasingly demanding. Simple analyzers have become the exception and instead the function is extended with additional components in order to meet the gas analysis requirements. This is part two of three posts on the topic, we will exemplify setups with NOx converter, Ozone destroyer, which is used with our CLDmini technology and regulated pump.

With TRACE-GAS OEM Assemblies, you can easily configure your own analyzing solution. Our OEM assemblies will not only speed up your development process, but are also very small and work plug & play!

Over the recent years, we have developed solutions for many customers with different needs in sampling, communication and ambient conditions. Consequently, our product range of additional sensor components has increased over time. Now, we want to share these OEM assemblies with you.

Our OEM assemblies allow you to…

- Speed up your design and implementation process

- Save time analyzing and testing various products

- Use the modules plug & play

- Minimize the support effort with various suppliers

All our modules can communicate by CAN and require a 24V power supply. Preconfiguration allows the user to use it plug and play. Our OEM assemblies can be combined with our OEM sensor or can be used standalone in a customer configuration.

NOX Converter

In combustion processes NOX is used as a sum parameter for nitrous oxide (NO) and nitrous dioxide (NO2). Often, the emission limits for both NO and NO2 are regulated by only the sum parameter NOX. This allows to add a conversion step prior to the sensor and only measure one of the gases, in this case NO.

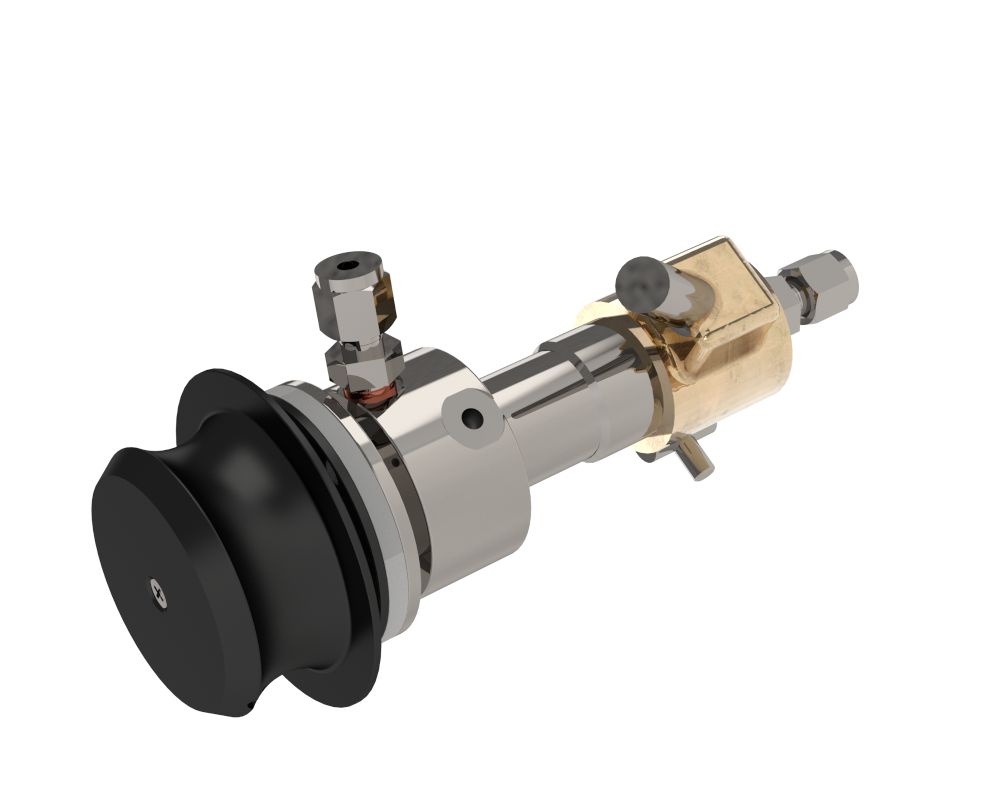

The NOx converter consists of a heated cartridge containing converter material and thermal insulation. The insulation enables effective heating and constant temperatures. By catalytic reduction, the NO2 molecules are converted into NO while being guided through the NOX converter. The conversion is done with an efficiency of up to 98%.

The NOX converter has been developed for our chemiluminescence detector (CLD, see example below), which is known as the reference method for NO and NOX measurements. After entering the analyzer, the sample gas is guided through the NOX converter before being mixed with ozone (O3) inside the reaction chamber. With that technique, the user can measure NOx as a sum of NO and NO2. Optionally, NO2 can be determined separately by bypassing the NOX converter repeatedly or by using a second reaction chamber (CLDdual).

The NOx converter stands out by its high efficiency, it’s compactness and flexible use cases. Not only CLD techniques can profit from it but also other sensors like NDIR. As the converter material might degrade over time, an easy access to change the material is given.

Overview:

- Consists of heated cartridge and insulation

- Conversion of NO2 → NO

- Efficiency up to 98%

- Compact

- Flexible use with different technologies

- Exchangeable material

Chemiluminescence analyzer with built-in NOX converter

NOX converter – available with or without insulation

Ozone Destroyer

When using chemiluminescence (CLD) techniques to measure NO or NOX, Ozone (O3) is produced during the measurement. Ozone is an irritant gas and can lead to nosebleeds and pulmonary oedema as well as breathing difficulties. It is very harmful to human bodies and should therefore never be inhaled. Guiding ozone into an exhaust line is not feasible in some cases and exhaust lines might not be available. For that and for reasons of personal workplace safety, Ozone is recommended to be destroyed directly after leaving the CLD sensor.

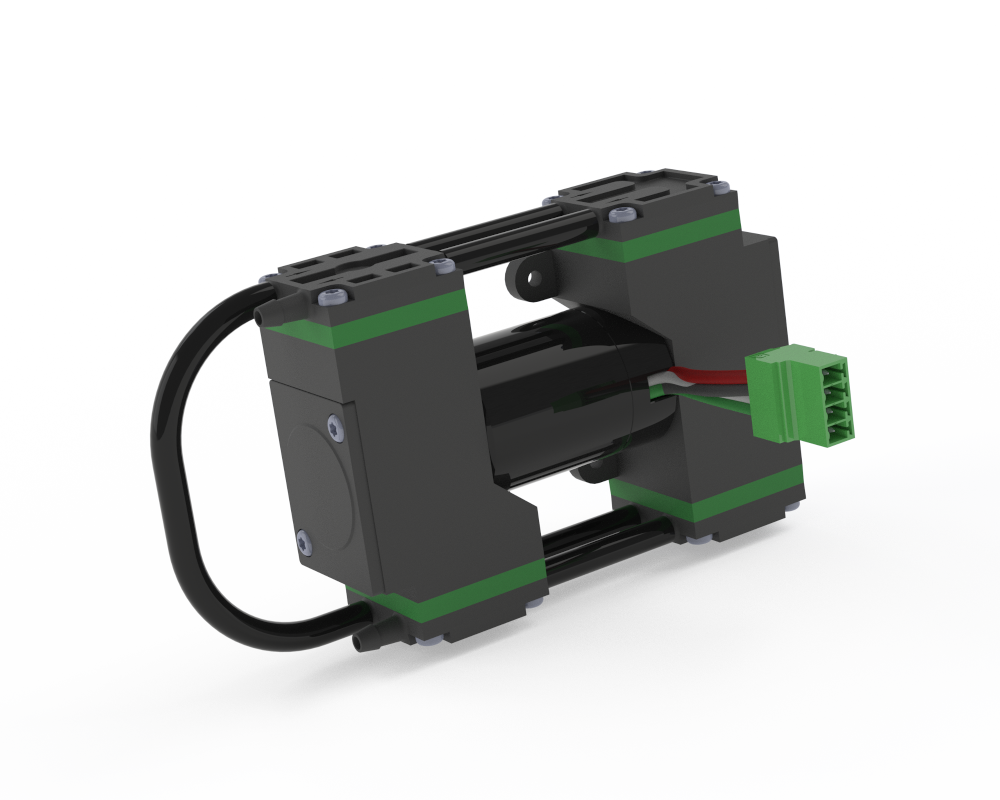

Inside the Ozone Destroyer there is a temperature element as well as a catalyst material, surrounded by insulation for efficient heating. The heating element only requires a power supply and is self-regulating its temperature. On both sides there are stainless steel connectors for an easy and plug & play use.

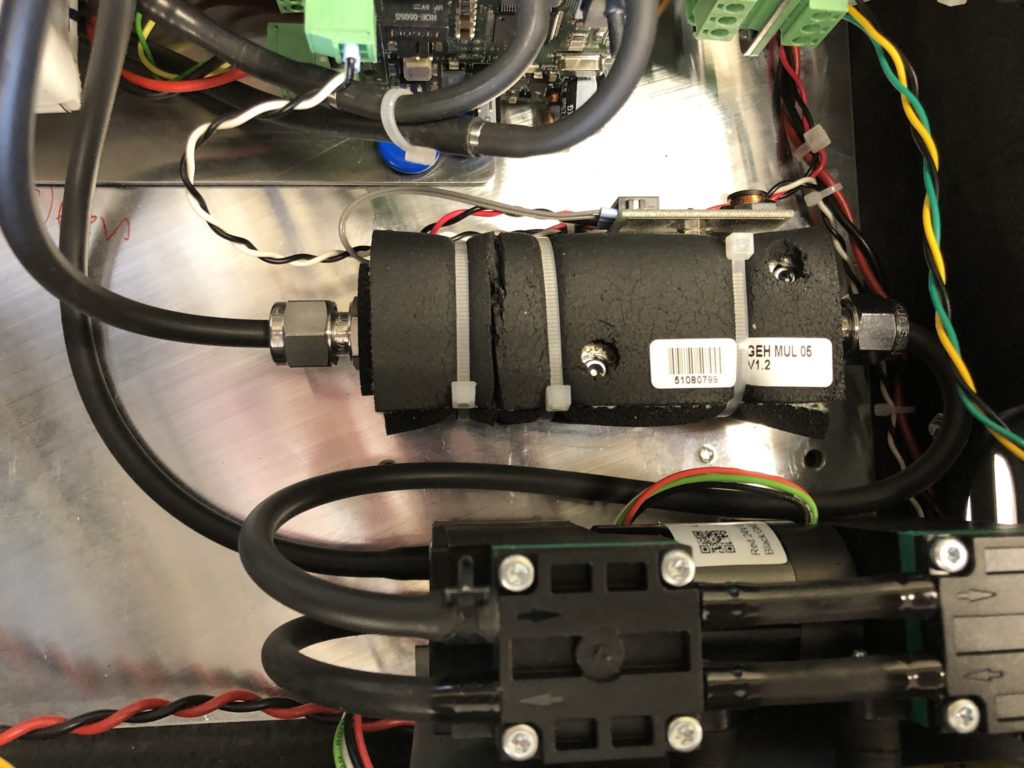

The Ozone destroyer is used with our CLDmini technology. However, the application range can be extended to whatever process needs to be “cleaned” of Ozone. The example below shows an example of a portable CLDmini application mounted inside a small box. The box is being used for NOX Kickdown measurements of vehicles. In order to protect the users from Ozone leaving the sensor, the Ozone Destroyer is placed at the end of the CLDmini Sensor.

The Ozone Destroyer is very compact and is therefore ideal as an OEM solution, which is limited in space and weight (like the KickDown NOX box). Furthermore, smart design and material selections make it very cost efficient.

Overview:

- Destroys Ozone (O3) by catalyst material

- Protects the user and allows easier measurement setups

- Heating element to avoid condensation

- Compact and cost efficient

- Ideal for portable use with CLDmini

Ozone destroyer in our CLDmini with NOx sensor

Built-in ozone detroyer

Ozone destroyer

Regulated Pump

Gas analyzing systems (except some in situ techniques or passive sampling) require pumps for various functions. A sampling pump typically extracts gas from one more positions in the process to the analyzer unit. In some cases, a second pump for the pre-sampling unit is advantageous. Depending on the application, the installed sensor and the gas matrix, the pump must fulfill different requirements. For short response times or if long sampling lines are applied, usually pumps with high gas flow are used. Furthermore, if high adsorbing gases (like NH3, H2O2, NOX, SO2) are measured or if the sensor itself requires vacuum conditions (like LAS, CLD), the pump is operated at typically low pressure in order to achieve best measurement results. However, gas flow and pressure are not the only pump parameters to be considered. Further requirements might be: resistance against corrosive gases, power regulation input, compactness for limited spaces, low oscillation impact and many more.

Through many years of experience in gas sensing we have figured out pumps suitable for all applications individually. For each measuring task we have pumps configured with certain flow, pressure, material, regulation input and size. Even a tiny condensate pump for our gas cooler can be found at TRACE-GAS.

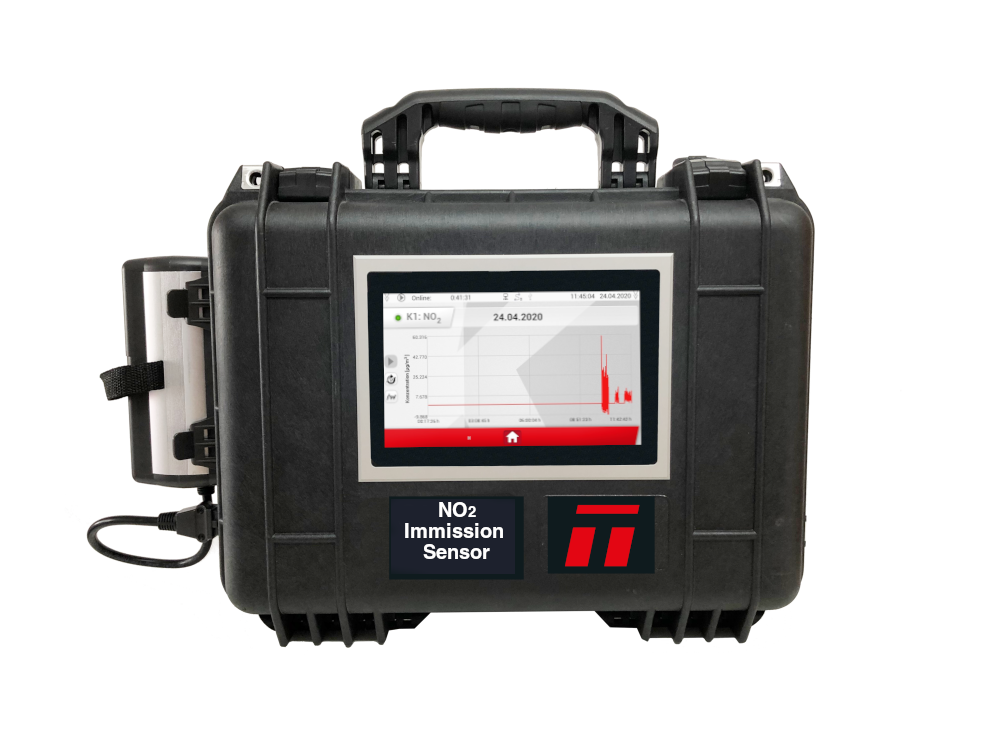

The example below shows a pump solution for portable imission monitoring of NO2. It is quite compact and operates at low power consumption. A power regulation input is used to maintain stable conditions for pressure and flow during the measurement.

Overview:

- down to 1.5 mbar

- up to 21 l/min flow

- with and without pressure regulation

- suitable for all our gas sensors

- customized material and electrical connections

Gas pump

Mobile No2 Immission Measurement

PAS immission module

Stay tuned for part 3 of our OEM assembly special with more component combinations. Meanwhile don’t hesitate to reach out to us with any questions.