Over the past few years, the requirements for gas analyzers have become increasingly demanding. Simple analyzers have become the exception and instead the function is extended with additional components in order to meet the gas analysis requirements. In this blog post, which is the first of three posts on the topic, we will exemplify different assembly setups to give you an overview on possibilities and to inspire you to think out of the box to meet your gas analysis needs.

When you have certain expectations on what requirements have to be met, when conducting gas analysis in your application it is often a long and tiring process to find the right components. A large number of inquiries have to be sent out and many offers have to be obtained. Once the right parts have been found, testing is required to ensure that they can be integrated and adapted to existing sensors, etc. This process costs a lot of time and money.

With TRACE-GAS OEM Assemblies, you can easily configure your own analyzing solution. Our OEM assemblies will not only speed up your development process, but are also very small and work plug & play!

Over the recent years, we have developed solutions for many customers with different needs in sampling, communication and ambient conditions. Consequently, our product range of additional sensor components has increased over time. Now, we want to share these OEM assemblies with you.

Our OEM assemblies allow you to…

- Speed up your design and implementation process

- Save time analyzing and testing various products

- Use the modules plug & play

- Minimize the support effort with various suppliers

All our modules can communicate by CAN and require a 24V power supply. Preconfiguration allows the user to use it plug and play. Our OEM assemblies can be combined with our OEM sensor or can be used standalone in a customer configuration.

Analog Output Module

For many applications using PLCs, an analog output signal is still the easiest way to go. By controlling the electrical current, the concentration values transmitted by gas sensors are converted into an analog signal.

The analog output module consists of 3 analog outputs, which can be used for different types of measured gases. Depending on the customer’s configuration the analog output can be tuned from 0 – 24 mA. Furthermore, up to four 24V highside switches and one 5V output can configured for e.g. warning lamps in case emission limit values are exceeded. As most of our OEM assemblies, the module is communicating via CAN with further devices.

The analog output module has been developed as component for our ready-to-use analyzers as well as for customer OEM solutions, which require analog output signals. The below picture shows a set of NDIR sensor and analog output module used for a continuous emission monitoring (CEMS) application in Asia. In order to speed up the implementation, customers can use the analog output module together with our NDIR sensors without the need of any configuration step. The three outputs are used for monitoring the emission limits for CO, SO2 and NO in exhaust gas.

The analog output module can be used with NDIR sensor plug & play. Furthermore, its cost efficiency and compactness make it ideal for low cost CEMS applications.

NDIR sensor and analog output module

Overview:

- 3x analog output, configurable 0 – 24 mA

- digital outputs for exceeding emission limit warnings

- compact and cost efficient

- works plug & play with our NDIR sensors

Electrochemical O2 sensor

In combustion processes an important parameter is the remaining oxygen content in the exhaust gas. It gives information about the ratio between the provided air and fuel. Since oxygen is not absorbing in the infrared region, an electrochemical oxygen sensor can be a useful accessory to NDIR sensors.

The module consists of the electrochemical sensor element, which is mounted into a stainless-steel mounting component. It is fitted with two pipe connections and a cable for connecting to the NDIR sensor. The complete module is leak tested during manufacturing.

The module has been developed for automotive industry, in which the remaining oxygen content inside the exhaust gas plays an important role for the combustion process control as well as the exhaust gas aftertreatment components.

The advantage of electrochemical sensors is their cost efficiency and compactness. Additionally, the sensor can be used plug & play with our NDIR sensors without any learning command.

Overview:

- Electrochemical oxygen sensor element

- Stainless steel mounting plate with pipe connections

- Works plug & play with our NDIR sensors

- Ideal for oxygen monitoring in exhaust gases

NDIR Demonstator with an electrochemical O2 sensor

O2 sensor – Electrochemical sensor

Gas Cooler module

In applications like combustion processes the sample gas typically contains a lot of moisture. If heated sample lines and heated sensors are not applicable, the sample gas must be dried in order to avoid any condensation in the following components. Typically, the gas is constantly cooled down to 4°C dewpoint and moisture is removed. Besides, cross interference to water is minimized and the measurement results become even more stable.

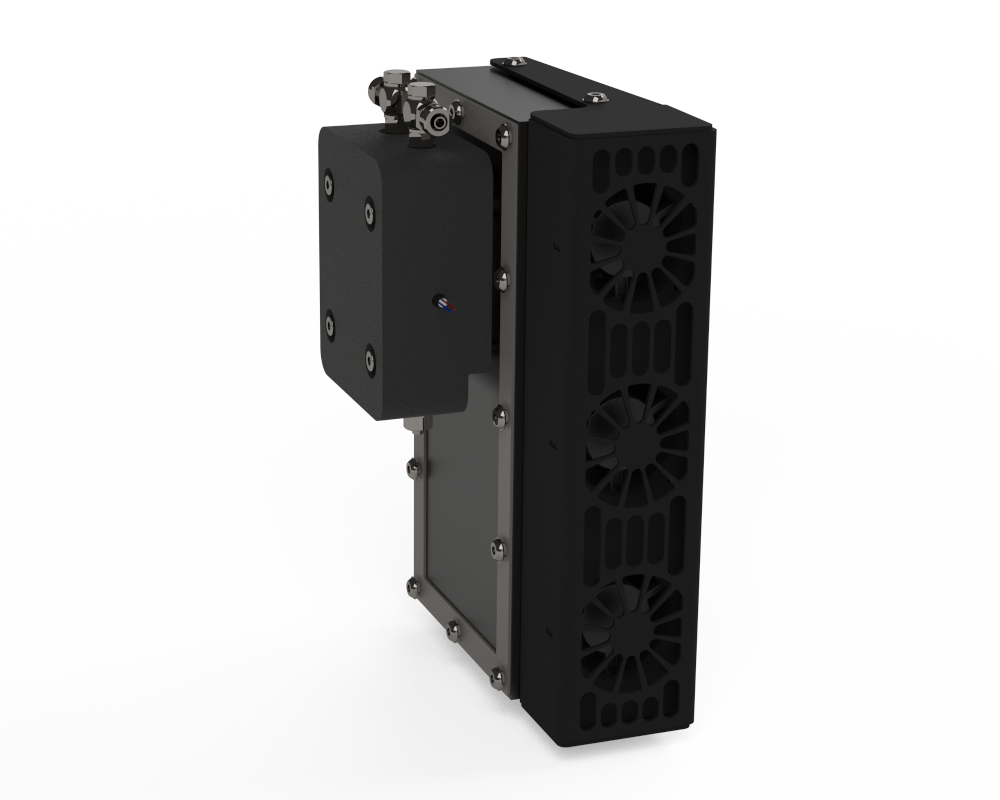

The gas cooler module consists of a compact gas cooler and a temperature control unit. A gas flow is guided through a special designed aluminum unit. The surface of the aluminum unit is mounted to the cold side of a Peltier element at the inside of the analyzer, from which the thermal energy is transported to its hot side out of the analyzer. The thermal energy is further dissipated by a compact heat sink with small fans mounted to it. Additionally, a small pump is continuously removing the condensed water to the outlet of the analyzer.

The gas cooler is a cost efficient and compact alternative to existing coolers. It is used for measurements in automotive industry as well as for analyzing sulfur dioxide emissions on ships.

Like a holiday reading book, its outer dimensions are only 205x140x50 mm. In its usage on ships the gas cooler has shown high robustness and low power consumption, which make it also ideal for portable applications.

Overview:

- Consists of gas cooler & temperature control board

- Size: 205x140x50 (dimension outside the housing)

- Cascaded peltier element for heat dissipation

- PT100 sensor for temperature supervision

- Compact heat sink & fans for efficient heat dissipation

- Outlet for condensation pump

- Robust and low power consumption

- Ideal for portable applications

CEMS-in-a-box with gas cooler

Gas cooler for oem asemblies

Note: Our temperature control board can be used for further control functions simultaneously (e.g. housing temperature)

Stay tuned for part 2 of our OEM assembly special with more component combinations. Meanwhile don’t hesitate to reach out to us with any questions.