We recently launched a new particle measurement technology under our umbrella brand KNESTEL. Particulate measurement as part of the main inspection of diesel vehicles will come into effect in the next 2 years in most of Europe. Therefore we are offering valueable OEM solutions for particle counting!

The automotive industry is facing new regulations – counting of soot particles as an integral part of the exhaust emission test of diesel cars. Everything you need to know about our OEM particle measurement technology consisting of a charging module, sensor module, ion separator and Volatile Particle Remover (VPR) comes into play here. The system can be easily cleaned and can be used as a standard solution as well as modularly. This means that adaptation to individual requirements is also no problem. Of course, the particle measuring technology complies with PTB specifications and can therefore be used throughout Europe without any worries.

At KNESTEL, we have been working on measurement modules for counting these particles for some time and are now providing potential partners in the industry with the appropriate particle measurement technology:

✅ modular setup consisting of charging module, sensor module, ion separator and Volatile Particle Remover (VPR).

✅ OEM use and demo setups possible, e.g. in case housing

✅ complies with PTB-A specifications

✅ Easy to clean with air or soap solution

✅ diffusion charging requires no consumables / liquids

The modules can be used as an OEM solution or in the form of pre-assembled modules, so adaptation to individual requirements is no problem. The innovative particle measurement technology complies with the PTB-A specifications and can therefore be used throughout Europe without any worries.

What makes our particle measurement technology special?

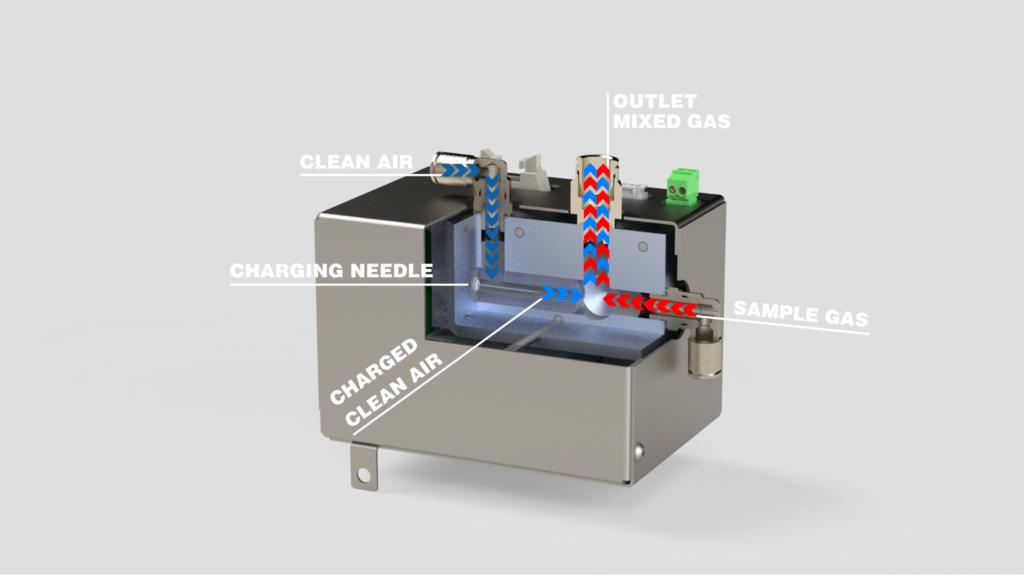

Ions are generated in the charger module, which then charge the particles at the mixing point with the exhaust gas. The mixing chamber is integrated in the charger module. Clean air is charged, so the corona needle is not contaminated. We call this the Clean Charging Technology!

Easy replacement of the corona needle via service opening in the non-calibratable part is a great advantage of our technology. Also electrical start-up and self-diagnosis is possible via charger current. Charging modes can be varied betweeen pulsed as well as continuous charging modes.

The Netherlands lead the way

The Netherlands will be the first country in Europe to start mandatory particle measurement for diesel vehicles on July 1, 2022. “We are excited to support our partners in the Netherlands with KNESTEL particle measurement technology to facilitate the control of diesel particulate filters and make the air in Europe cleaner!”, announces our managing director Markus Knestel.

From 2022 on, a particle count must then be performed on diesel cars during the PTI (Periodic Technical Inspection) in Holland. According to one estimate, there are between 100,000 and 125,000 diesel cars in the Netherlands that would fail the test because their particle filter is defective or has been removed, causing the vehicles to emit more particulate matter than legally permitted. In fact, EURO 6 diesel vehicles with a functioning particle filter are normally veritable “particle dust vacuums” and filter not only the vehicle exhaust but also the ambient air. Thus, the number of particles in the exhaust gas is completely independent of the amount of particulate matter in the ambient air. Even an increase in particulate matter in the intake air by a multiple does not lead to an increase in the emission rate.

Find more info here: https://knestel.de/en/solutions/automotive/particle-counting/