Through the photoacoustic principle, light is converted into sound waves when it interacts with gas molecules. Although the sound waves cannot be perceived directly by the human ear, the acoustic signals can be measured using microphones and the molecular concentration can be determined.

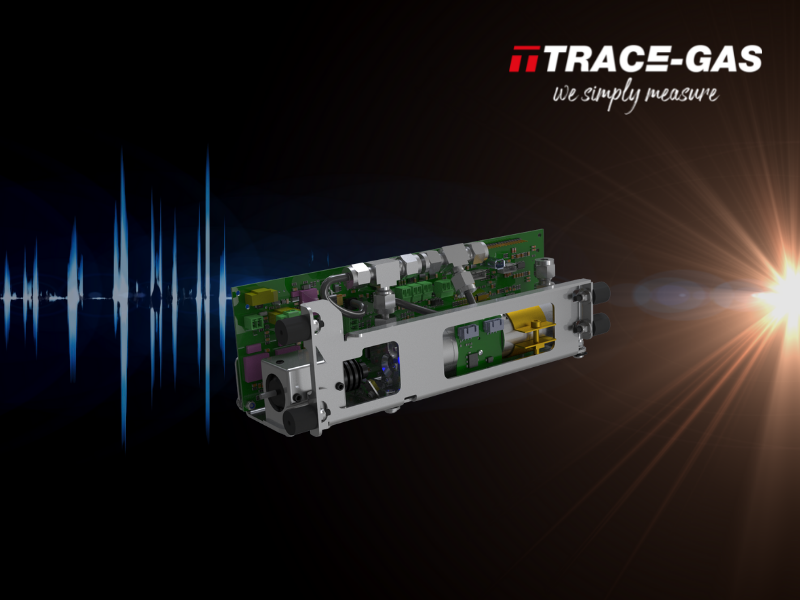

This amazing principle is used in the TRACE-GAS PAS sensors to determine the concentration of gases. The photoacoustic technology platform offers many design options to realize low-cost and highly sensitive quantification of trace gases. Depending on the gas molecule, a wide variety of light sources can be used: from the ultraviolet to the mid-infrared range, LEDs, UV lasers, ICLs or even QCLs can provide the ideal solution for a measurement task.

Photoacoustic gas sensors can make an important contribution in the field of air quality monitoring. Air purity is of utmost importance for the environment as well as for our health. The level of toxic gases such as nitrogen dioxide (NO2) in our environment must therefore be continuously monitored.

Despite low detection limits, no cross sensitivities as well as a highly stable zero point, photoacoustics is still not widely used in air quality monitoring. Until now, one had to choose between very accurate but expensive laboratory instruments like FTIR, chemiluminescence, NDUV or low-cost sensors, which are mostly drift sensitive and show cross sensitivities to other gases (e.g. ozone). With the PAS immission sensor for the measurement of NO2, TRACE-GAS, the gas

analysis brand of KNESTEL Technologie & Elektronik GmbH, has developed a low-cost solution with optimal measurement performance for air quality monitoring.

The PAS technology platform offers, in addition to the stationary measurement application, completely new possibilities for gas analysis. For example, battery-powered use on drones (e.g. NO2, NH3, CH4) is made possible and vehicles with defective exhaust aftertreatment systems can be “sniffed out” in road traffic. Further applications of the technology are in the field of industrial process monitoring (e.g. acetylene, H2O) or purity monitoring of hydrogen (e.g. NH3, CO, H2O).

You can also find more info about the technology here: https://www.trace-gas.com/technology-las-pas-cld-ndir/photoacoustic-spectroscopy/